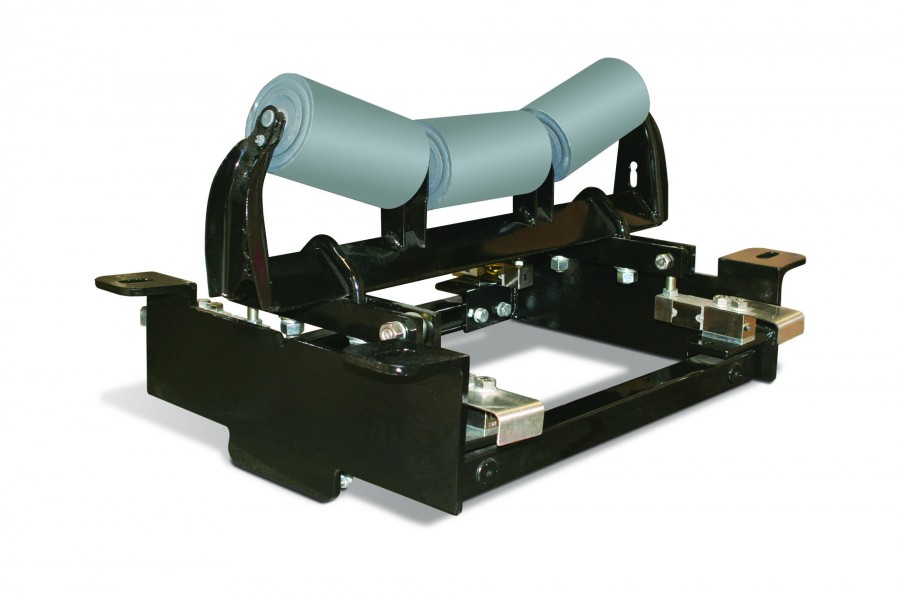

They are systems that are generally used to measure the flow rates of materials (coal powder, flour, grain, sugar, etc.) that can flow with the free fall principle in the industry. In addition to the flow, they work completely like belt scales due to their working logic. The location of the velocity information is changed to the multiplication coefficient. Because this time, the material falling from the load is measured as a different weight due to the acceleration caused by the fall. Since the height is constant, they cause a proportional load change as a constant coefficient.

Impact scales are used in places where belt scales, flow scales, and silo measurement systems cannot be applied, such as vertical floors. Its main uses are to measure flow and dosing.

Features

2 different Total indicators

+/- 0.25% accuracy (20-100% flow range)

Monitorable instantaneous flow, load indicators

3200 measurements per second

Modbus RTU/ASCII

The determined amount of material flow rate

0-10V /4-20mA Analog Output

External display output

Ability to set quantities without entering the menu

RS232/485 or Ethernet ModbusTCP controlled connectivity, fully integrated operation with PC/PLC, etc.

USB Reporting

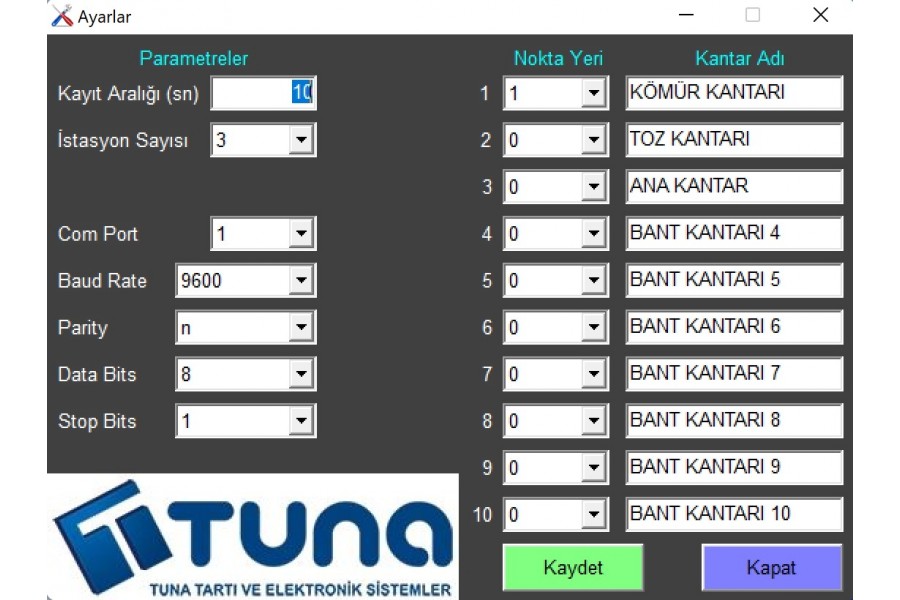

PC Monitoring and Reporting software (optional)

| MULTIPLICATION SCALE / IMPACT SCALE: |