Tuna Belt Scales are produced in 3 categories as T-BS500 - T-BS1000 - T-BS2000.

Tuna T-BS Electronic Belt Scales measure the flow weight of the material carried on the conveyor belt. Thanks to its practical installation, it is an important data source for businesses and also saves labor, time, and capital.

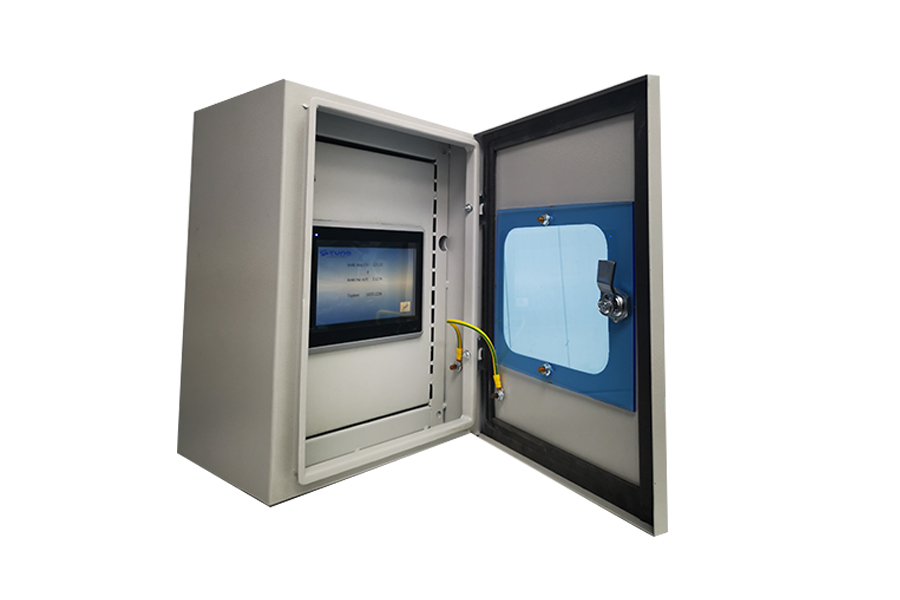

Tuna T-BS Belt Scales consist of LPR100 Indicator, integrated with load cells, the bidirectional encoder that can read speed, and a system control panel. With the ability to connect to the external display screen, it provides the opportunity to monitor the number of goods passing over the conveyor band, instant flow, and total. Instant information, weighing information can be archived daily, monthly, or at desired time intervals with Tuna-Band Weighbridge Tracking Program on PC-Computer. The archived information can be examined graphically and provides reporting in excel format. Tuna LPR-100 control terminal is shown on the screen as t/h, kg/h, kg/m, m/h, or kg.

In order for a belt scale to provide the said sensitivity rates, the following criteria must be met;

(a) If the existing conveyor belt is old, attached, torn, and deformed, and in case of vibration, the error rate may change. In order to prevent the weighing units from being affected by weather conditions in terms of measurement accuracy, if necessary, a protective device will be taken by you.

(b) The existing or potential vibration in the system will be prevented. If the condition that the vibration effect is not greater than the minimum permissible error (0,5-1-2%) cannot be met, the weighing pan area must be supported by steel construction.

(c) All measuring systems have a minimum capacity proportional to the maximum capacity, with constant accuracy, and this is 30% in belt scales. Inflow values below the minimum capacity, an error greater than the given error rate may occur.

(d) In order for the system to operate at the given error rates, the material passing through the band must be fed continuously above the minimum capacity value. These error values will not be provided in cases where the material does not flow in a continuous regime, the goods are fed intermittently, the goods are transported in batches, or the material flow below the minimum capacity value.

(e) In angled bands, the band angle should not exceed 18-20 degrees. From this angle, the goods start to flow backward on the conveyor, which affects the measurement result in the wrong direction due to backward slip.

(f) The error rates given are for dry material. Errors caused by the moisture of the material or water filtered from the belt are outside these error rates. If there is stickiness on the material, the necessary scraper assembly should be made by you.

(g) It is necessary to eliminate roll misalignment.

Features

Fast and Precise Measurement

Industrial Type IP66 Protection Class

2 Relay Outputs, RS232/RS485 Connection Possibility

Tuna Reporting Program

Steel/Stainless Steel

Easy Adjustment and Calibration with Keys

Turkish, English Usage

Stainless Steel, IP66 Loadcell

Bidirectional Speed Reading

Easy Installation and Assembly Opportunity

Control of Belt Speed at a Certain Level

Option

Tuna Reporting Program

External Display

Contents

2 Stainless Steel Load Cells

1 x 2 Junction Box

1 Tachometer Bidirectional

1 Controller (Analog Output)

1 piece of Clipboard

50 meters Communication Cable

T-BS500

Maximum Capacity (t/h): 500

Average Capacity (t/h): 250

Minimum Capacity (t/h): 50

Speed (m/s): 1.0-2.0

Measuring Error (*) (%) : 0.5 / 1 / 2

MODEL T-BS500

Accuracy Class 0.5

Flow rate (max) 1000 t/h

Belt Speed (max) 2.5 m/s

Capacity 10-100 kg/m

Band Angle (max) 25°

Band Width (max) 800 mm

Distance between rollers 500-1000 mm

Load Cell TUNA SP4

Encoder Bidirectional

Indicator T-Lpr100

Tuna T-BS Bant Kantar Kurulum ve Montaj Kılavuzu

Tuna T-BS Bant Kantar Kurulum ve Montaj Kılavuzu